What is a brine injector?

A brine injector is a vital tool used in meat processing to inject a brine mixture—typically consisting of water, salt, and various seasonings—into meat products. The primary purpose of a brine injector is to enhance the weight, flavor, and tenderness of the meat, while also ensuring that it cooks more evenly and retains moisture. This equipment is particularly valuable in the production of processed meats such as ham, turkey, and chicken, where brining helps improve both texture and taste.

How Does a Brine Injector Work?

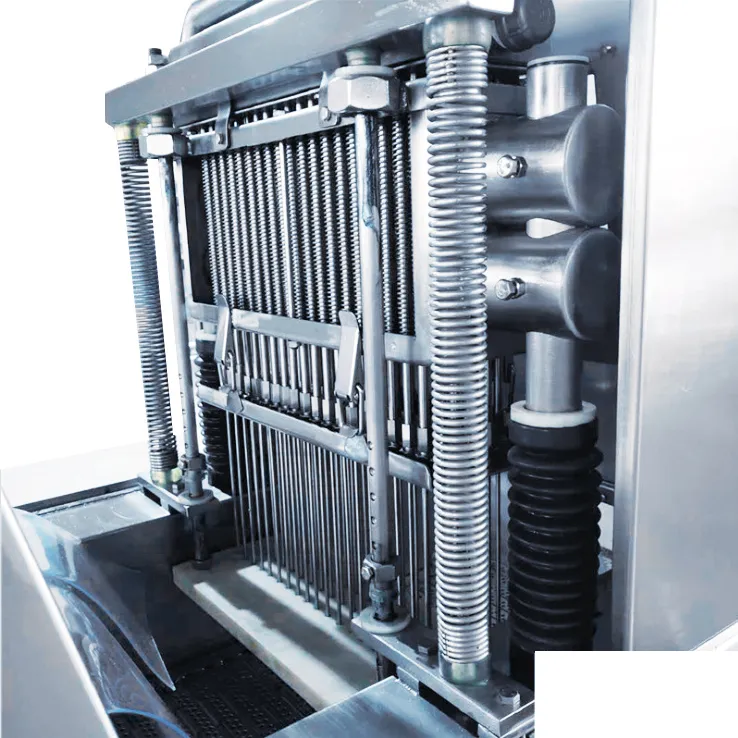

The process is straightforward: the meat is fed into the injector, where needles puncture the flesh and inject a flavorful brine solution. Depending on the machine’s design, these needles can work in different ways to distribute the brine mixture into the meat.

Most traditional brine injectors on the market use a quad-needle design, where four needles are grouped together. While this setup sounds advantageous, it often leads to several challenges in meat processing. For example, if one needle strikes a bone or encounters resistance, all four needles may retract, resulting in an incomplete brine injection. This reduces the overall effectiveness of the process and can lead to inconsistent product quality.

A more advanced alternative to the quad-needle design is the single needle brine injector, which offers several significant advantages.

1. Increased Brine Injection Efficiency

One of the most notable benefits of a single needle brine injector is its ability to inject brine more efficiently and precisely. Each needle in a single needle system operates independently, which means that if one needle encounters a bone or other obstruction, only that needle will retract. The remaining needles continue to inject brine into the meat. This independent operation ensures that more brine is delivered into the meat, resulting in improved flavor, weight gain, and moisture retention. In turn, these factors lead to better cooking results and a higher-quality product for the consumer.

The precision of single needle injectors also allows for brine to be injected closer to the bone, which is especially important for meats with uneven structures or bones that can block the flow in quad-needle systems.

2. Better Filtration and Easier Maintenance

Another advantage of single needle brine injectors is their superior filtration systems. Over time, brine mixtures can contain seasoning particles, pepper flakes, or other solid ingredients that may clog the injector needles. In a quad-needle injector, these blockages are harder to address because all four needles are interconnected. Cleaning and maintaining these systems can be time-consuming and challenging.

In contrast, single needle injectors tend to have better filtration systems that reduce the likelihood of clogging. Even if a clog does occur, it is much easier to remove and clean the needle in a single needle system, as each needle operates independently. This makes the entire maintenance process faster and more efficient, saving time and improving overall production workflow.

3. Cost-Effective and Easier to Clean

From a cost perspective, single needle brine injectors also offer a significant advantage. Single needle systems are not only easier to maintain but also more cost-effective to repair. If a needle becomes damaged or clogged, it can be replaced individually, rather than having to replace an entire set of four needles, as would be required with a quad-needle system. This reduces the cost of repairs and replacement parts, making single needle injectors a more budget-friendly option for meat processors.

Additionally, the design of single needle injectors makes them easier to disassemble for cleaning. Since each needle can be removed individually, it’s simpler to ensure thorough cleaning and reduce the risk of contamination. A cleaner brine injector also results in better food safety, as it minimizes the potential for cross-contamination between batches.

Conclusion

In conclusion, a MEAT BRINE INJECTOR is an indispensable tool for meat processors, offering a reliable way to enhance the flavor, texture, and weight of meat products. The single needle brine injector stands out as the superior option, providing increased injection efficiency, easier maintenance, and lower operational costs. With these advantages, processors can ensure a more consistent and high-quality product, while also improving operational efficiency.

For companies looking to enhance their meat processing capabilities with a high-quality brine injector, Foshan Aokai Machinery Technology Co., Ltd. offers top-of-the-line brine injectors designed for precision and durability. Contact us today to learn more about how our products can elevate your production process.