Sausage making is an art that combines tradition, innovation, and a careful selection of ingredients. Central to this craft are the fillers used to create the distinctive flavor, texture, and appearance of sausages. Additionally, modern advancements in technology have revolutionized the production process, with sausage filling and twisting production lines streamlining efficiency and consistency.

The fillers employed in sausage making vary depending on the type of sausage being produced and regional preferences. However, several common ingredients play a fundamental role in shaping the character of sausages.

At the heart of sausage production lies the meat. Typically sourced from pork, beef, chicken, or a blend of meats, this primary ingredient provides the foundational flavor and protein content of the sausage. The selection of meat influences the final taste profile, with each variety offering unique nuances and characteristics.

In conjunction with meat, fat serves as a crucial filler in sausage making. Often derived from pork, fat contributes moisture, richness, and succulence to the sausage. While pork fat is favored for its flavor, alternatives such as beef or lamb fat may also be utilized to achieve desired taste profiles.

Salt, another essential filler, enhances flavor and acts as a preservative, extending the shelf life of the sausage. Proper seasoning is key, striking a delicate balance to ensure optimal taste without overwhelming other flavors.

Spices and herbs further enrich the sensory experience of sausages, adding depth, complexity, and aroma. Common ingredients like black pepper, paprika, garlic, onion, sage, and thyme infuse distinct flavor profiles, distinguishing one sausage from another.

In addition to traditional fillers, modern sausage production benefits from innovative equipment like sausage filling and twisting production lines. These automated systems streamline the manufacturing process, increasing efficiency, consistency, and output.

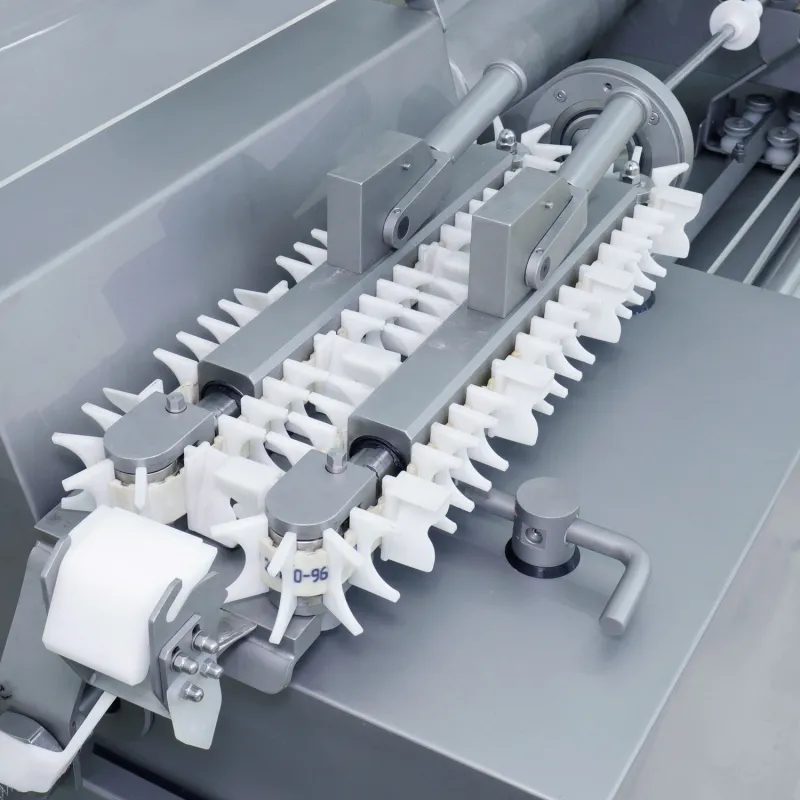

Sausage filling and twisting production lines are equipped with precision machinery designed to accurately measure, mix, and stuff sausage casings with the desired filling. Advanced controls ensure uniformity in portion size and distribution of ingredients, resulting in consistent quality across batches.

Furthermore, these production lines incorporate mechanisms for twisting and linking sausages, facilitating seamless packaging and presentation. Automated twisting ensures uniformity in sausage shape and size, optimizing visual appeal and consumer satisfaction.

In conclusion, the fillers used in sausage making, combined with advancements in technology like sausage filling and twisting production lines, converge to create a harmonious blend of tradition and innovation. Whether crafting classic recipes or exploring new flavor combinations, the art of sausage making continues to evolve, delighting palates and preserving culinary heritage.