Industrial Production Process of Shrimp Slippery

2024-07-23 18:54Over the years, shrimp skewers have been widely used in the hotpot industry and have also been extensively promoted in other dining settings, such as barbecue, cooking, and shrimp skewer specialty snack shops. The market size of shrimp skating has reached the level of billions, becoming an independent category. With the increasing demand for food quality, the market for high-quality ingredients has risen, and shrimp paste, as one of them, has received more and more attention and favor. Below, we will introduce an industrial production process for shrimp slides.

Process flow: Meat thawing → Meat processing → Vacuum stirring → Filling and packaging → Quick freezing → Packing.

Basic ingredients: 38% shrimp, 15% golden line fish paste, 16% pig fat, 2.1% cassava starch, 1.2% salt, 2.1% white sugar, 0.3% sodium tripolyphosphate, 0.05% D-isoascorbate, 0.2% monosodium glutamate, 0.16% spice, 24% ice water.

Operation points

1、 Meat thawing

Using frozen shrimp (or fresh shrimp) that have passed quarantine inspection as raw materials, natural thawing (ambient temperature ≤ 11 ℃) is preferred, followed by water spraying thawing (water temperature ≤ 11 ℃), and thawed to a center temperature of -2-2 ℃.

2、 Meat processing

Drain the surface moisture from the thawed shrimp, cut it into small pieces of appropriate size, and use a 25mm mesh plate to prepare the trimmed raw materials, including golden thread fish paste and pig fat, for later use. The temperature of the raw materials should not exceed 4 ℃.

3、 Vacuum stirring

Place shrimp meat, golden thread fish paste, pig fat, salt, sodium tripolyphosphate, etc. in a Meat mixer and stir for 2 minutes; Add the remaining ingredients and continue stirring. Vacuum degree requirement: 0.08-0.09MPa; The stirring and vacuuming time is 10 minutes. Please add the weighed ice water in batches during this process.

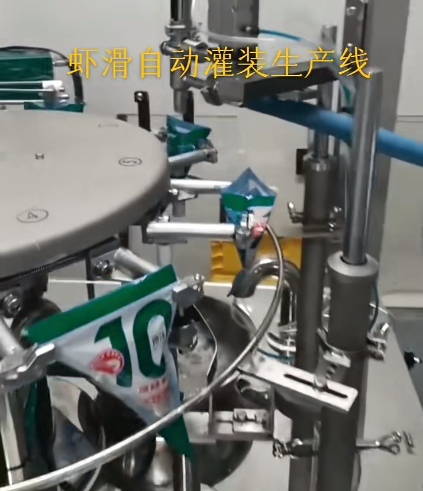

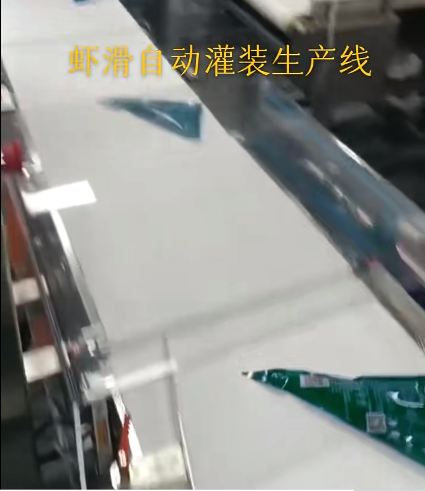

4、 Filling and packaging

The shrimp mince that has been stirred is quantitatively filled using a Vacuum filler machine and vacuum sealed using Prawn chops filling and packaging production line.

5、 Quick freezing, boxed storage

After packaging, the shrimp paste needs to be immediately frozen. Freezing can effectively maintain the original tissue structure of the shrimp paste, reduce juice loss, and the taste is not much different from freshness. Pick out defective products such as damages and non-standard printing, then pack them with metal detectors and store them below -18 ℃.

Foshan Aokai Machinery has developed a comprehensive set of advanced equipment and production lines to support the industrial production of shrimp slippery. From the meat mixer for thoroughly blending the shrimp meat, to the specialized prawn chops filling and packaging production line, and the hot pot sauce automatic processing machine - Aokai's solutions streamline the entire manufacturing process. The use of cutting-edge technologies like the vacuum filler machine ensure consistent quality and high efficiency.