What and how should do in meat sausage processing workshop

2023-03-17 17:42Food safety has always been a key concern for the country! For human beings, food safety is a matter of health and well-being! For companies, food safety is the lifeblood of their business! In modern society, with the rapid development of technology, in order to strictly and effectively control the processing of products and ensure the quality of meat products, it is necessary to develop operational standards and specifications for each processing step of the product.

The meat sausage processing process is generally divided into: meat/selection - grinding - mixing/chopping - vacuum filling - steaming process - cooling - automatic packaging High-temperature sterilisation - coding, etc.

The following is an introduction to the various aspects of the meat processing process that should be noted according to the product's processing process.

I. Meat (picking) process

A raw meat into the workshop before thawing, to remove cartons or woven bags and other packaging, but the inner packaging bags can not be removed

B Each type of raw meat should be selected according to the relevant criteria (e.g. blood, hair, broken bones, etc.)

C Foreign objects and impurities are stored in a designated place to avoid being mixed with the selected meat.

D Meat must be stored centrally on the floor, rinsed with water and disinfected before use

E The waste bins in the production line must be kept at a certain distance from the raw meat and must be cleaned every shift

F When changing meat types (e.g. chicken, pork, beef, etc.), the worktop must be pre-rinsed

II. Meat grinding/supplementation process

A For grinded and weighed raw meat, label with name, date, total number of loads, etc.

B If special ingredients are ground, the equipment must be cleaned in time

C Handing over of auxiliary materials, ensuring that the packaging is not damaged and that the quantity is confirmed.

iii. Mixing, chopping and marinating processes

A When handing over raw materials and auxiliaries to the previous process, do so in a single pot

B For mixing or direct addition of auxiliary liquids to the product, the process must be carried out in strict accordance with the requirements of the process

C For the mixing of the auxiliary liquid, it should be clearly marked (including the date, product name, etc.)

D After the ingredients have been dispensed, they are recorded and labelled (e.g. date, product name, weight, number, etc.)

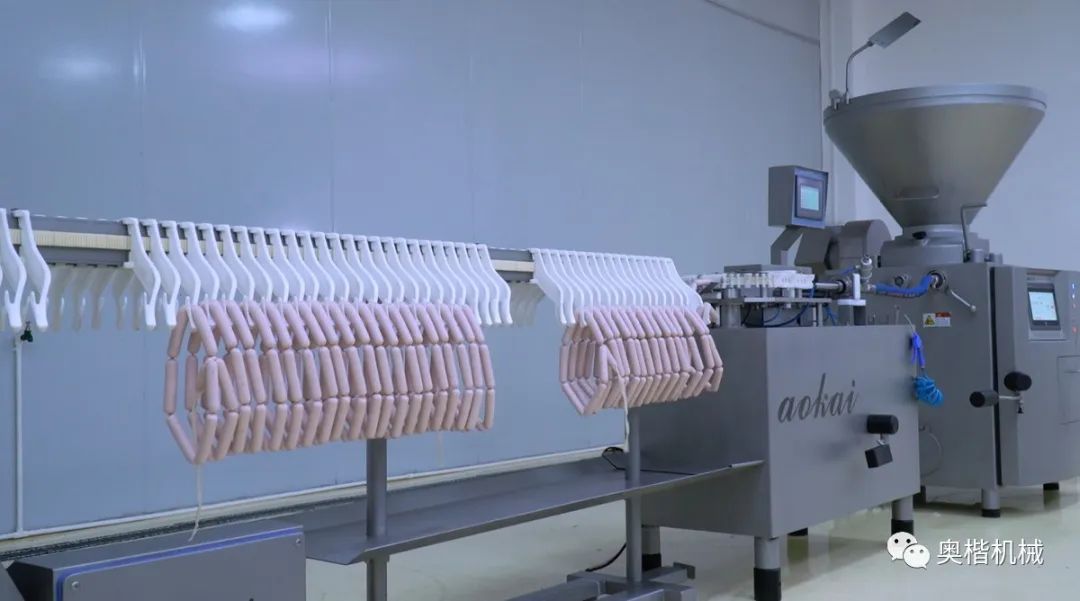

IV. Vacuum filling process

A For each pot, it is advisable to make a pre-filling system to determine in advance if there are any abnormalities in the filling and to keep records

B The shelves used for product placement must be cleaned and brushed to avoid foreign substances on the product surface

C When using natural casings, sort for foreign matter; when filling protein casings, ensure that the worktop is free of water

D Clean the equipment when filling different products to avoid the effects of sensitive additives

E For high-temperature products, fillings that need to be re-filled during operation must be gold-probed before filling to avoid mixing with screws and other metal objects

V. Steaming and drying process

A Before using the equipment, ensure that the oven is free from dirt and that the steam pressure supply is clean, etc.

B. Do not mix raw and cooked products to prevent cross contamination

C Make sure that the temperature and time parameters are correct before and after the product is processed

D Unsteamed floor products and floor products after cooking must be disposed of according to regulations.

VI. Automatic packaging process

A Electronic scales and other tools should be calibrated before use

B The packaged products should be passed through the gold probe, for abnormal products should be stored with special treatment

C The difference in colour and quality should not be too obvious when packaging multiple products

D Negative gram products should be well marked, special treatment

Ⅶ,high-temperature cooking sterilization process

A Do the relevant pre-pasteurisation inspection records, such as water temperature, etc.

B The number of layers of baskets should not be too high when the product is handed over (basically six layers or so)

C During the sterilisation process, ensure that the product is below the liquid level

D The cooling temperature of the sterilised product should not exceed 20°C before it is loaded into the basket.

Ⅷ, spray code process

A out of the warehouse products can not directly touch the ground, need to add a mat board or floor basket

B Negative grams of products stored separately, according to the provisions of the re-add processing

C Leakage and foreign body products to be detected, special treatment

D The coding date should be clear and error-free, and the invalid label should not be allowed to be attached to the product.