What is the process of sausage packaging?

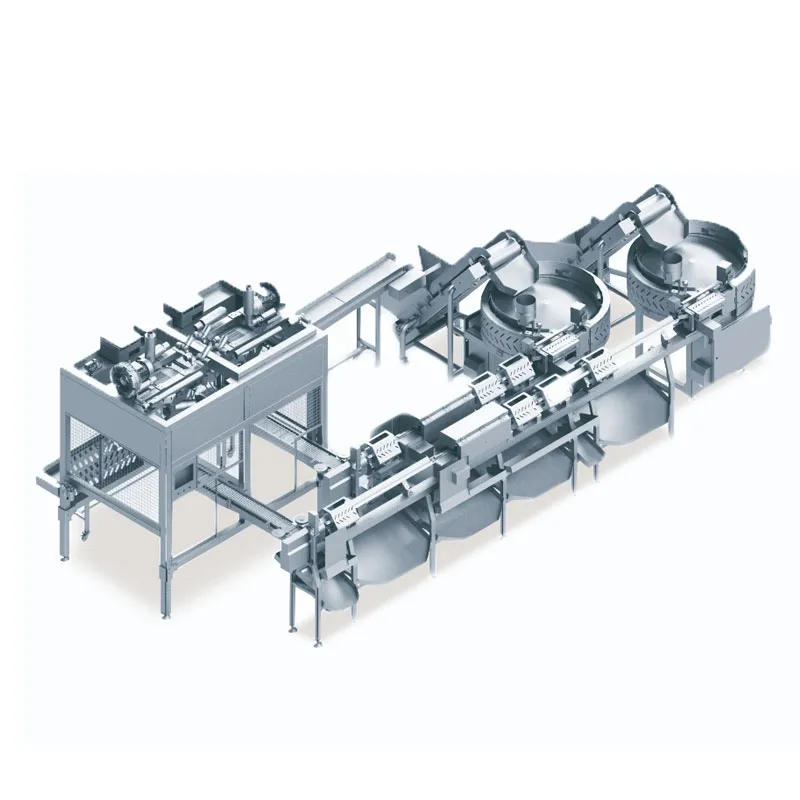

2024-05-06 18:12Understanding the Automated Packaging Process in Automatic Packaging Sausage Production Lines.Sausages are a popular and versatile food item enjoyed worldwide. However, behind the scenes of every delicious sausage lies a meticulous packaging process, particularly in modern automated production lines. Lets delve into the intricate steps involved in the automated packaging of sausages.

Preparation of Packaging Materials:Automated sausage packaging begins with the preparation of packaging materials. This involves ensuring an adequate supply of packaging materials such as film, trays, or casings, depending on the type of sausage being packaged.

Sausage Loading:Once the packaging materials are ready, the sausages are loaded onto the production line. This can be done manually or automatically, depending on the level of automation of the production line.

Weighing and Portioning:In many automated Automatic Packaging sausage production lines, the sausages undergo weighing and portioning before packaging. This ensures uniformity in size and weight, which is crucial for both quality control and meeting consumer expectations.

Packaging Machine Setup:Next, the packaging machine is set up according to the specifications of the particular sausage product being packaged. This includes adjusting settings such as sealing temperature, film speed, and portion size.

Sealing and Forming:The packaging machine then seals the sausages in their respective packaging materials. This may involve forming individual packages or sealing them in bulk, depending on the packaging requirements.

Labeling and Printing:After sealing, labels containing essential product information such as ingredients, nutritional content, and expiration dates are applied to the packaging. Some automated packaging machines also have the capability to print directly onto the packaging material.

Quality Control Checks:Throughout the packaging process, automated quality control checks are conducted to ensure that the sausages meet specified standards for freshness, safety, and integrity of packaging.

Final Packaging and Inspection:Once the sausages are sealed, labeled, and quality-checked, they are prepared for final packaging. This may involve grouping them into larger containers or placing them on trays for display.

Packaging Into Cases or Cartons:In the final stage of the packaging process, the packaged sausages are placed into cases or cartons for transportation and distribution. Automated systems may handle this step, including palletizing for efficient storage and shipping.

Cleaning and Maintenance:After completing the packaging process, the equipment undergoes thorough cleaning and maintenance to ensure optimal performance for future production runs.

In conclusion, the automated packaging process in Automatic Packaging sausage production lines involves a series of precise steps aimed at ensuring efficiency, consistency, and quality in the packaging of sausages. From weighing and sealing to labeling and final packaging, each stage plays a vital role in delivering fresh and flavorful sausages to consumers around the globe.

Foshan Aokai machinery specialize in providing a full range of sausage processing machines solution for domestic and abroad customers. We have su cessfully enter into interational

market and shipped to many countries, including United States, Mexico, Philippines, Zambia, Vietnam, Thailand etc. We get good reputation on our quality products from our customers.