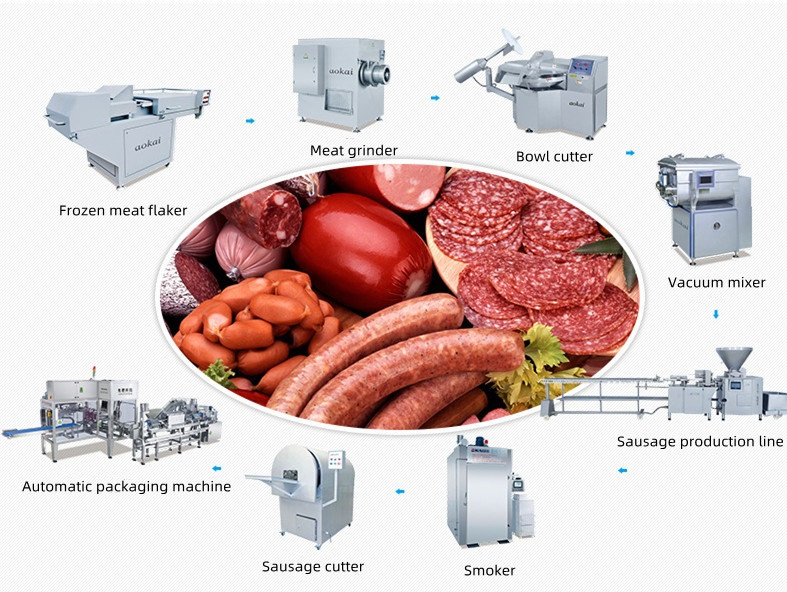

Automatic Packaging And Stacking Sausage Production Line

- Information

- Product Description

- Video

Automatic Packaging And Stacking Sausage Production Line

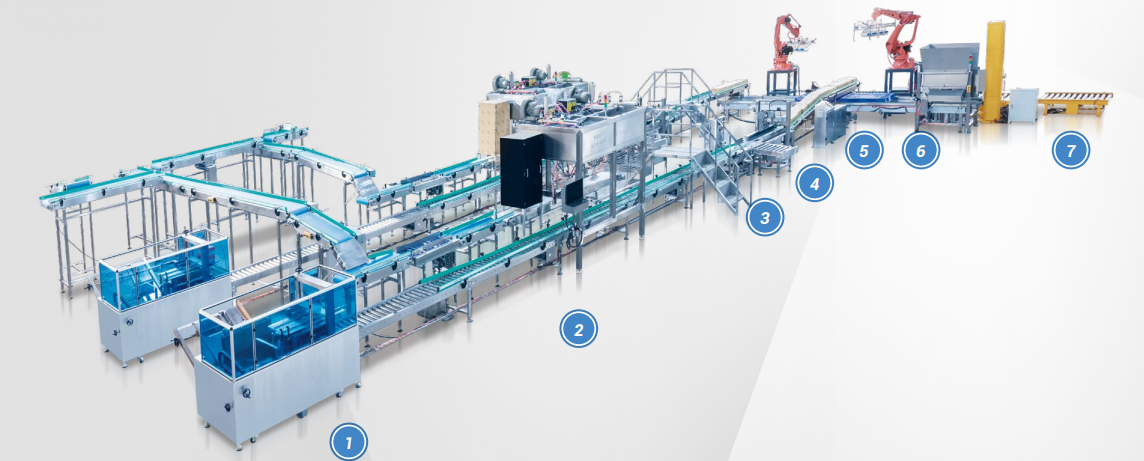

Our company independently develops the robotic unpacking and packing machine matching the palletizing manipulator to realize the automation of packing and palletizing. The input and output of the entire equipment line realizes intelligence, automation and high performance.

The workflow of the fully automatic packing and stacking sausage production line: connect the quick-freezing tunnel, rely on visual inspection, and then open the box, pack and seal the box with the robot, and use the palletizing robot to stack the carton on the pallet, during which dynamic weighing and coding functions can be added.

The automatic packing and palletizing production line has a wide range of applications, and can be widely used in the automatic packaging and palletizing of bags, boxes and other items in petrochemical, food, medicine, feed, grain, building materials and other industries. Using automated production processes is more reliable and more economical.

Features:

1. It can be designed according to the standard, or customized according to the specific needs of the customer and the site rather than the standard design.

2. The robot packing adopts automatic suction type, and the suction cup is designed according to the packaging bag. High-speed picking, high precision and high efficiency.

3. As an auxiliary equipment of the assembly line, the palletizer has high automation, high positioning accuracy, fast operation, flexibility, sturdiness and durability, and large load, ensuring high output and high quality, greatly improving the economic benefits of the enterprise, and greatly reducing the production cost.

4. The structure design of the palletizer is optimized, the action is stable and reliable, the adjustment is convenient, and it is suitable for a variety of palletizing types.

5. The palletizing process is completely automatic, and no manual intervention is required during normal operation, and it has a wide range of applicability.

6. The working environment has been significantly improved, personal physical labor has been reduced, and it has played a key role in reducing staff and increasing efficiency.

Quality requirement:

1. The probability of More or Less is 3‰ after successful commissioning of the equipment.

2. Sausages shall not be damaged or broken during bagging. If the upstream products are damaged or broken, that the above requirement is not applicable.

3. Error probability of bagging is less than 5 ‰.

The robot packing adopts automatic suction type, and the suction cup is designed according to the packaging bag. High-speed picking, high precision and high efficiency.

The structure design of the palletizer is optimized, the action is stable and reliable, the adjustment is convenient, and it is suitable for a variety of palletizing types.