Customer Visit from Thailand to Foshan Aokai Machinery Technology Co., Ltd. for Single Sausage Twisting Production Line and Product Training

2024-09-10 11:46Foshan Aokai Machinery Technology Co., Ltd., a leading manufacturer of advanced food processing machinery, recently welcomed a delegation from Thailand for a detailed factory visit and product training session. The Thai client, a well-established food manufacturer, was particularly interested in Aokai’s Single Sausage Twisting Production Line, a high-efficiency system designed to streamline the sausage production process, improve output, and ensure consistent product quality. This visit provided the client with the opportunity to explore the equipment firsthand, gain technical insights, and receive comprehensive training on its operation and maintenance.

The Customer Visit

The Thai delegation, including senior executives and technical staff from a major sausage production company, visited Aokai’s headquarters to evaluate the Single Sausage Twisting Production Line in action. The client’s goal was to enhance their production capacity and improve the efficiency of their sausage manufacturing process by incorporating more automated and high-performance equipment into their production lines.

Aokai’s team organized a structured agenda that included product demonstrations, technical discussions, and a hands-on training session to ensure that the Thai client fully understood the features, benefits, and operational procedures of the equipment. The visit was an essential part of the client’s decision-making process as they evaluated Aokai’s machinery for future investments in their manufacturing facility.

Product Demonstration: Single Sausage Twisting Production Line

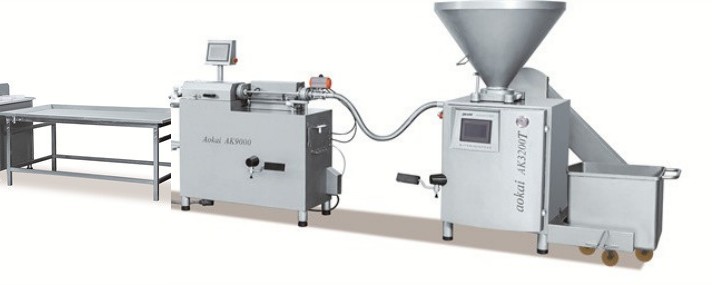

The highlight of the visit was the live demonstration of Aokai’s Single Sausage Twisting Production Line. This fully automated line is designed to improve the efficiency of sausage production by automating the twisting and sealing of sausages, which is traditionally a manual process. The Thai clients were able to see firsthand how the production line works seamlessly from start to finish.

The Single Sausage Twisting Production Line incorporates several advanced features that impressed the visiting delegation:

Automatic Twisting and Sealing

The line automates the twisting process, significantly reducing the need for manual labor. It ensures that each sausage is twisted at the perfect interval and sealed tightly, preserving the quality and freshness of the product. The client was impressed by the machine’s precision, as well as its ability to handle sausages of various sizes and types.High Output and Efficiency

Designed for high-volume production, the line operates with excellent speed and precision, capable of processing large quantities of sausages in a short amount of time. The Thai client was particularly interested in how the line could increase their production output while reducing labor costs.User-Friendly Interface

The production line is equipped with an intuitive control panel that allows operators to easily adjust settings, monitor production speeds, and troubleshoot if necessary. The delegation appreciated the machine’s ease of use, which would help minimize training time for their staff.Hygienic Design

The hygiene standards of the equipment were another important factor for the Thai client, as food safety is a top priority in food processing. The Single Sausage Twisting Production Line features a hygienic design, with easily cleanable surfaces and sealed components to prevent contamination.

Product Training Session

After the demonstration, Aokai’s technical team conducted an in-depth training session for the Thai delegation. The training covered various aspects of operating, maintaining, and troubleshooting the Single Sausage Twisting Production Line to ensure that the client’s staff could use the equipment efficiently and effectively.

The training session included:

Machine Operation

Aokai’s engineers walked the delegation through the operation of the production line, explaining how to set up the machine, adjust parameters for different sausage sizes, and optimize production speed. The client’s staff had the opportunity to ask questions and get hands-on experience with the equipment under the guidance of Aokai’s technical experts.Maintenance and Troubleshooting

Proper maintenance is essential to ensure the longevity and optimal performance of any food processing equipment. Aokai’s team provided detailed instructions on routine maintenance tasks, including cleaning, lubrication, and inspection procedures. They also demonstrated how to identify and troubleshoot common issues that may arise during operation, ensuring that the client’s staff would be able to quickly address any problems that might occur on the production line.Safety Protocols

Food production machinery must meet high safety standards, and Aokai made sure to highlight the safety features of the Single Sausage Twisting Production Line. The training covered safety protocols for operating the equipment, ensuring that the client’s team could work in a safe environment without compromising on efficiency.Production Optimization

In addition to training on basic operation and maintenance, Aokai’s engineers shared best practices for optimizing production efficiency, improving product consistency, and reducing waste. These insights were particularly valuable for the client, who is focused on increasing production capacity while maintaining the quality of their sausages.

Factory Tour and Quality Assurance

After the training, the delegation was given a full tour of Aokai’s manufacturing facility. The tour provided an opportunity for the Thai clients to see the entire production process—from machine design and engineering to assembly and quality testing. Aokai’s commitment to precision manufacturing and quality control was evident throughout the factory.

The clients were impressed by Aokai’s stringent testing procedures, including the rigorous performance and safety checks each machine undergoes before leaving the factory. This attention to detail reassured the delegation that they were investing in equipment that met the highest international standards.

Strengthening the Business Relationship

The visit provided a valuable opportunity for Aokai and the Thai client to strengthen their business relationship. By offering a comprehensive demonstration and detailed training, Aokai was able to build trust and confidence in its products and services. The Thai delegation left the visit feeling reassured that Aokai’s Single Sausage Twisting Production Line would meet their production needs and help improve their manufacturing efficiency.

The training also ensured that the client’s staff would be well-equipped to operate and maintain the equipment, which is crucial for long-term success and minimizing downtime in the production process.

Conclusion

The visit from the Thai delegation to Foshan Aokai Machinery Technology Co., Ltd. was a highly successful and productive event. The hands-on demonstration of the Single Sausage Twisting Production Line, combined with the in-depth product training, allowed the client to make an informed decision about investing in Aokai’s equipment. Aokai’s commitment to providing exceptional customer support, training, and after-sales service was clearly demonstrated during the visit, reinforcing the company’s reputation as a trusted partner in the food processing machinery industry.

As Aokai continues to expand its global presence, the positive outcome of this visit strengthens its position as a leader in providing innovative, high-quality solutions to meet the growing demands of food manufacturers worldwide.